How to Prevent Water from Collecting and Pooling in Your Boat Cover

I can’t tell you the number of times I’ve been walking the docks and have seen boat covers in bad shape with pools of water in them. As water collects, it gets very heavy, which can weigh boats down to the point where they take on water through a scupper or even over a gunwale. Getting the water out often involves pumping or bailing as the weight of the water can easily be too much to lift. In addition, that much weight can bend stanchions or cause other boat damage. It is best to avoid the problem entirely, and that’s exactly what we’ll focus on in this article.

Preventing water collecting or pooling on your boat cover is best achieved by providing a proper boat cover support system or frame beneath the cover. Even if your cover has a snug fit, a little water can cause fabric to relax and create low points where there were none. Covers, especially tarps and other non-fitted styles, can also shift as they are subjected to winds and boat movement, which may create pooling points. Boat cover support systems can be installed by a professional, come in kits ready to self-install, or can be created from scratch as a DIY project.

Let the Pros Handle it

As you might imagine, hiring professionals is the most expensive option, but will usually yield the best results and take the least amount of your own time.

Shrink Wrap

If you have your boat professionally shrink wrapped, the team you hire will provide the framing necessary to prevent water collection points. Shrink wrap doesn’t sag since it fits tightly to your entire vessel. Be sure to discuss proper venting with the wrap team to avoid moisture on board and have them install a doorway to allow access for your periodic checks. Note that shrink wrap cannot be reused.

Custom Canvas

A custom solution will have the highest up-front cost, but you’ll be able to reuse the cover for many years. The cover-makers will provide you with the support framing you need and show you how to properly set everything up. After the first-time setup, it is generally up to the boat owner to install the framing and cover for the following years, so be sure to take notes! As with shrink wrap, the canvas team will make doors and vents to suit. With a fabric solution, it is very important that tie downs are taut and kept that way. It is a good idea to tighten straps and lines periodically while the cover is in use to prevent any sagging over time.

Photo Credit: northshorecanvas.net

DIY

If you are handy and want to save a few bucks, a do-it-yourself solution may be the way to go. You can find ready-made options out there or build a frame from scratch!

Ready to Install

Standard Boat Cover Support Pole

A boat cover support pole is likely the cheapest option but also the least reliable. I’ve seen plenty of these bent or on their side with covers full of water. Support poles usually have a convex endcap on the top or come with a fabric reinforcement patch to install where pole meets cover. They are most effective if used for a small area of cover such as in the forward seating area of a bowrider. If you use one, check on it often!

Pole and Strap Kit

Pole and strap kits are available for various boat sizes and types. They include a set of poles and straps to make a boat cover frame and are easy to install. The main drawbacks are quality and too few straps. Often the poles are made of thin aluminum or plastic and can easily bend. With only a few straps provided, there are often large areas where the cover can sag. Using such a system requires frequent checks to adjust and tighten the cover down as it relaxes over time. Here’s a little lifehack: if you go to a shrink wrapper, they should be able to sell you just the support kits, which are usually of better quality than the kits you’ll find in regular stores and online.

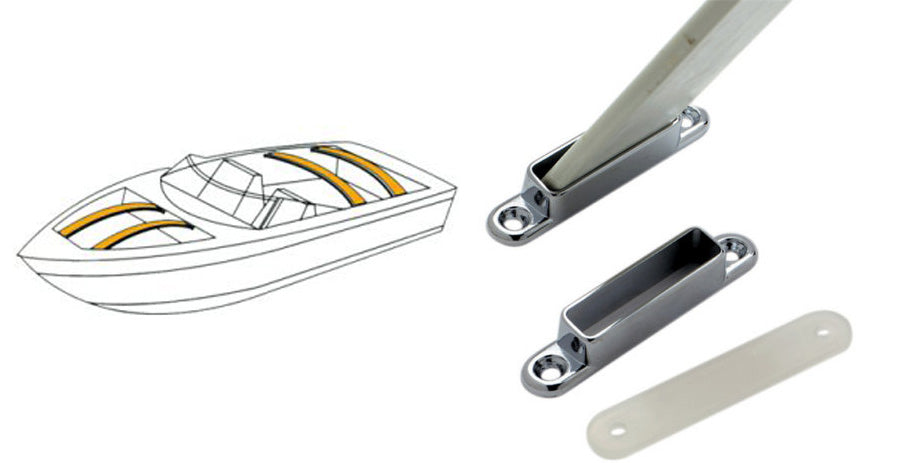

Bow and Socket Kit

The bow and socket support solution consists of flexible bows made of wood or fiberglass and sockets for the ends to fit into. Bows are made longer than the area covered so bend into arches to support the boat cover. Sockets are screwed into boat gunwales or are mounted to rails with clamps. It is important not to leave large gaps, so use enough bows to eliminate sag between them, and be sure to secure your cover down tightly. Check on your cover regularly.

Hanging Support

If you’ve got a ski tower, then another option for supporting your boat cover is a suspension system. Instead of a frame supporting your cover from the underside, this system suspends your cover using a line connected to your tower. The main advantage to this setup is ease of use. It only takes a second to hang your boat cover and the whole rig stays with the cover.

Photo Credit: hangtyte.com

Build to Install

PVC Tubing

One of the post popular build-your-own boat cover support solutions consists of white 3/4” PVC tubing available from any home or hardware store. With tubing and elbows you can make almost any shape of frame you need. Longer lengths of tubing can be formed into bows while elbows and T-junctions can be used to customize attachment points. While this method takes some thought as well as trial and error, the customization possibilities are endless. Note that bows may need upright poles at their high points for strength and stability.

Electrical Metallic Tubing

EMT can be used for a fully custom frame like the PVC solution above. Special clamps that allow you to connect the tubing at any angle are available (e.g. Kover Klamps) to make your frame. The advantage here is that your frame with be ridged and strong. The disadvantage is in creating your frame: it is difficult and requires special tools such as a tubing bender and tubing cutter. A 27’ power boat would require about 200’ of EMT.

Wood

Wood is the classic boat cover support frame solution. I’ve seen wooden frames that are almost as beautifully constructed as the boats themselves, especially on classic wooden sailboats. While these are reusable, long lasting, and strong, you’ll need some serious carpentry and engineering skills to construct a good one. With wood you need to ensure that any point of contact between frame and cover is smooth and/or reinforced to avoid abrasion as the cover shifts and moves in the wind. Wood frames are also quite heavy and bulky to store.

Final Thoughts

This article has listed several solutions for preventing water from pooling on your boat cover. The most important thing is that you choose one. Do not take the lazy way out by throwing a cover on your boat and leaving it for months on end with no support; you’ll regret it. The second most important thing is that you check on your boat regularly. No matter which option you choose, covers and frames can fail. With regular checks, you can catch failures early before damage occurs or even prevent problems entirely.Published

Recent Posts

Windlass Problems? Common Issues and How to Fix Them

Let's look at common issues with windlasses and how to address them:

1) Windlass Won’t Run in Either Direction

2) Solenoid Clicks, but Windlass Won’t Move

3) Windlass Lacks Power to Haul the Anchor

4) Rode Gets Jammed or Doesn’t Come In

Our history: a 20 year journey

Boat Cleaning Tips for Anglers: Keeping Your Vessel Spotless and Pristine

Avast, Ye Mariners! Master the Art of Docking: A Swashbuckling Guide for Boaters

Top Reasons to Keep a Boating Maintenance Log

4 Top Tips for Buying a New-to-you Used Boat

Bent Boat Anchor Shank: Common Causes and Prevention Tips

Prepare Your Boat For An Above Average Hurricane Season

Best Methods For Anchoring Your Jet Ski in Deep or Shallow Water

Best Options For Connecting Your Boat To WiFi Internet