Common Windlass and Anchor Line Snags and How to Prevent Them

If you use a windlass to help lower and retrieve the anchor on your boat, chances are that you've experienced the occasional snag, jam, or bind as your rode passes through the windlass. In this article, we will be covering the most common hang-ups that people experience and tips and tricks on how to avoid these mishaps in the future.

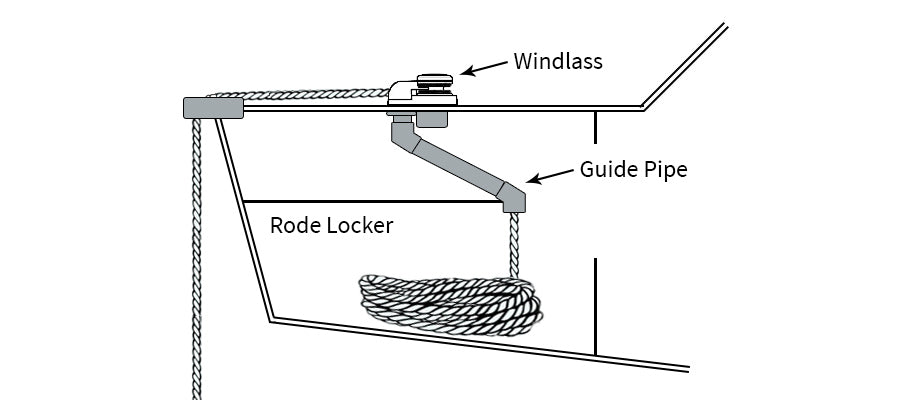

Scenario: Upon anchor retrieval, the anchor rode jams in the windlass on its way to the locker and must be manually helped into place at the bottom of the locker.

Solution: If your anchor rode is not coiling into the locker properly, you may need to install a guide pipe that helps align the rode directly to the bottom of the locker. This will help the rode coil more smoothly into the locker and will reduce the chance of it kinking along the way.

Scenario: Similar to the first issue, anchor rode can also jam the windlass when paying out the anchor due to kinks and binds that develop inside the locker.

Solution: To be able to pay out anchor line smoothly, the line must be kink-free inside the locker. If the line in the locker is kinked, resolve this by first removing the anchor from the line, then letting out all of the line into the water. With the line completely let out, reverse the boat a hundred yards or so to help the line unwind and remove the kinks. Next, retrieve the line with the windlass and allow it to naturally coil back into the locker. Then just reattach the anchor to the rode and you're good to go. If you still experience issues with the line kinking inside the locker, you may also need to add a guide pipe as detailed above.

Scenario: 3-strand or 8-plait rope does not feed smoothly and binds up at the windlass.

Solution: Over time, fibers in your line start to slowly weaken and deteriorate with regular use. If your line builds up a lot of salt, sand, or debris, these particles will only exacerbate the issue by acting as tiny teeth that further degrade the fibers in the line.

Luckily there is an easy DIY fix that many seasoned boaters rely on to extend the life of their anchor lines. Start by removing all of the anchor line from the locker and give it a good wash with a hose to remove any large particles that may be stuck to the rope. Then put the line in a large bucket or container and fill the container up with water. Add several tablespoons of fabric softener to the container and let the line sit in this solution for a couple of days. Once the soak is complete, hang the rope up to air dry for another day or two before returning it to the boat.

We also recommend performing this soak for all brand new anchor rode before its run through the windlass to condition the line properly. The fabric softener helps to remove the salt and dirt out of the line, which causes the line to deteriorate due to internal abrasions. Performing this maintenance once a year will keep your line soft and flexible, reducing the possibility of snags when running through the windlass. Soap and other oxygenated cleaners can be used in place of fabric softener, but bleach should never be used as it will actually degrade the line even further.

Scenario: When an anchored boat spins, the anchor chain twists causing the anchor to come up backwards in your bow roller.

Solution: Since it's difficult to prevent the boat from spinning once at anchor, this issue is most easily fixed by adding an anchor turner kit to your boat. An anchor turner kit includes a swivel that automatically twists your anchor as it is pulled to the bow roller. This tool ensures that your anchor is always oriented the correct way and eliminates the need to manually flip the anchor by hand.

Scenario: Your spliced anchor rode jams at the windlass where the rope meets the chain.

Solution: If your line to chain splice has become frayed over time, this section will begin to face difficulties passing through the windlass and will lead to jams. The more frayed the splice has become, the more often these jams will continue to occur. The only way to prevent this is to re-splice the line to the chain. The key to splicing your rode is to ensure that the rope section is not much wider than the chain section, so as to reduce the chance of hang-ups as the splice passes through the windlass. Splicing three-strand rope to the chain is a fairly straightforward process, but splicing double braided line to the chain is considerably harder. Most marine shops will be happy to professionally splice your rode together for a minimal charge, normally around $15 - $25.

Published

Recent Posts

Windlass Problems? Common Issues and How to Fix Them

Let's look at common issues with windlasses and how to address them:

1) Windlass Won’t Run in Either Direction

2) Solenoid Clicks, but Windlass Won’t Move

3) Windlass Lacks Power to Haul the Anchor

4) Rode Gets Jammed or Doesn’t Come In

Our history: a 20 year journey

Boat Cleaning Tips for Anglers: Keeping Your Vessel Spotless and Pristine

Avast, Ye Mariners! Master the Art of Docking: A Swashbuckling Guide for Boaters

Top Reasons to Keep a Boating Maintenance Log

4 Top Tips for Buying a New-to-you Used Boat

Bent Boat Anchor Shank: Common Causes and Prevention Tips

Prepare Your Boat For An Above Average Hurricane Season

Best Methods For Anchoring Your Jet Ski in Deep or Shallow Water

Best Options For Connecting Your Boat To WiFi Internet